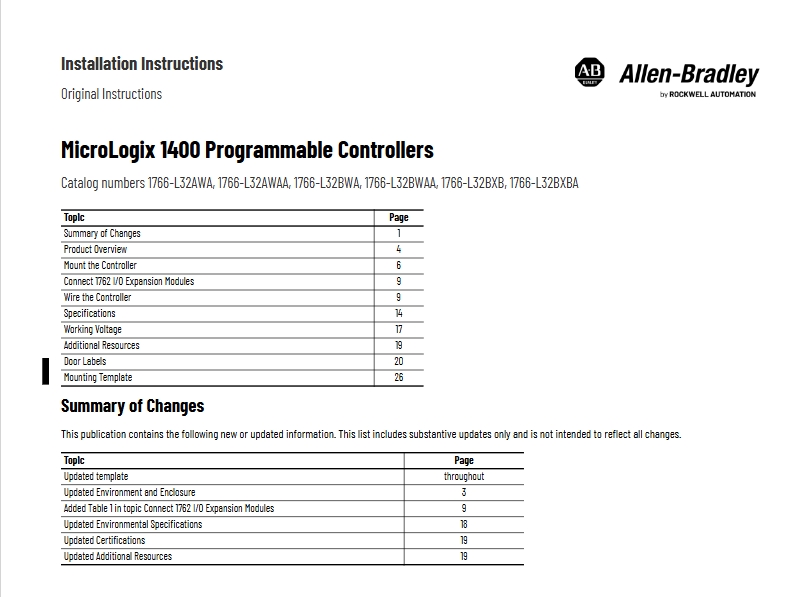

MicroLogix 1400 Programmable Controllers Installation Instructions

MicroLogix 1400 Programmable Controllers Installation Instructions Catalog numbers 1766-L32AWA, 1766-L32AWAA, 1766-L32BWA, 1766-L32BWAA, 1766-L32BXB, 1766-L32BXBA

MicroLogix 1400 Programmable Controllers Installation Instructions Read More »